Aeroacoustic sound sources, which result from turbulence of airflow around objects, can be a significant source of noise. When designing aerodynamic shapes, it is important to pay attention to details. This includes:

- choosing the right contours

- using smooth surfaces

- avoiding unnecessary edges that could disrupt air flow

Once the shapes are carefully designed, air resistance can be minimized, allowing vehicles to move more efficiently. That results in better fuel economy and a reduction of areodynamic noise.

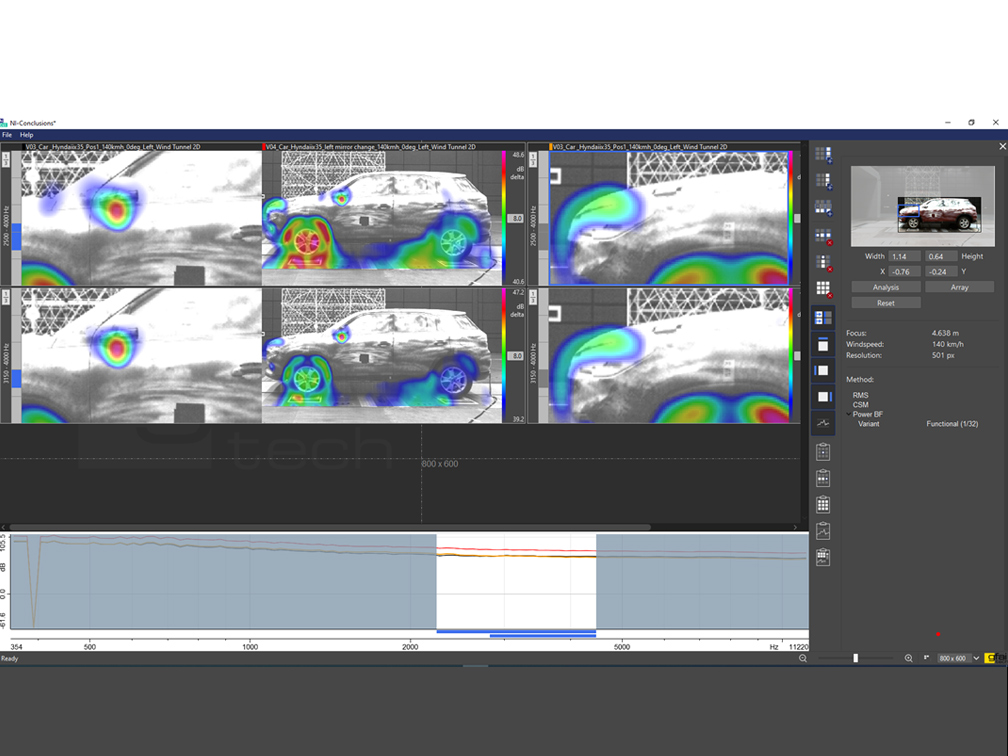

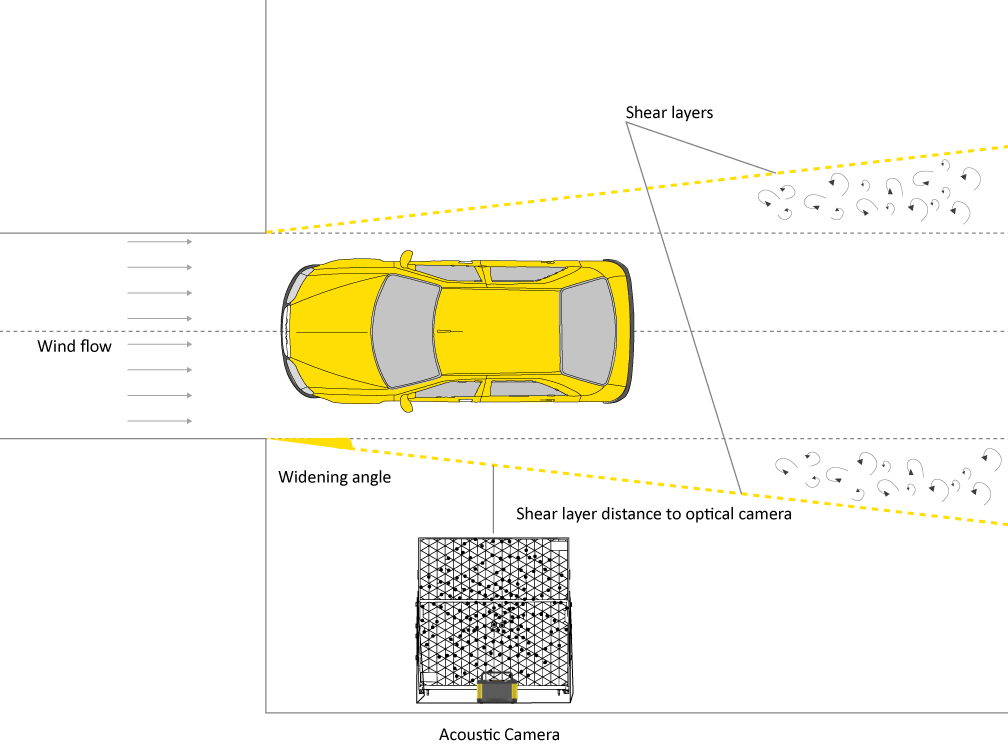

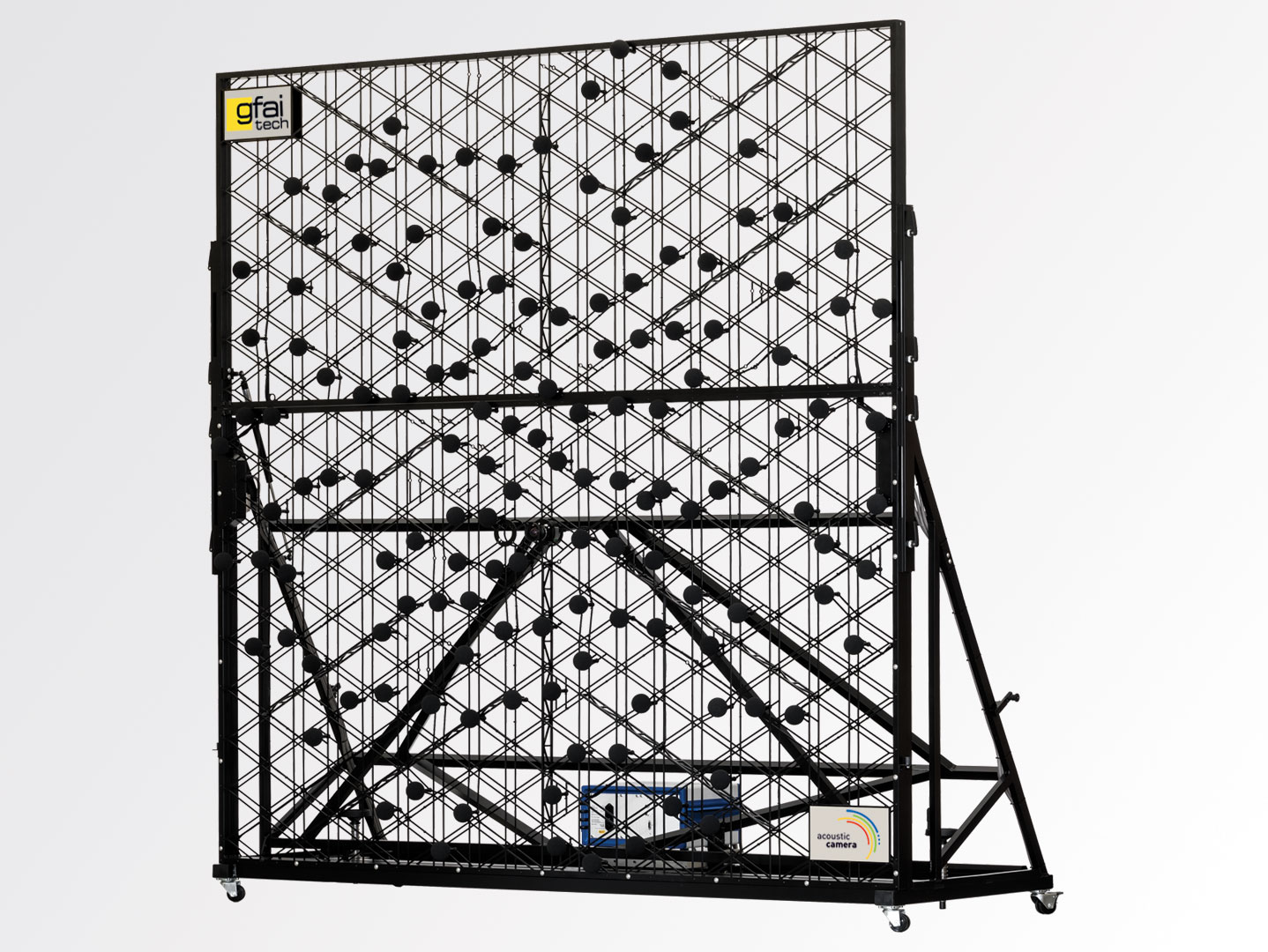

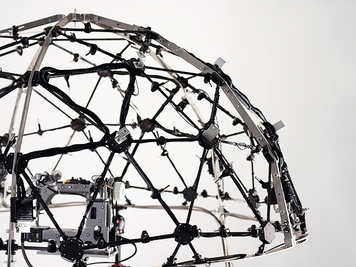

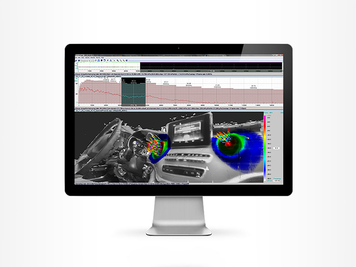

Our Acoustic Cameras are valuable tools when combined with wind tunnel testing in various industries, including automotive design, aerospace engineering, and wind turbine development. By integrating an Acoustic Camera into a wind tunnel setup, product developers such as vehicle manufacturers can effectively study and analyze the acoustic characteristics of aerodynamic models or components. Noise sources can then be precisely identified and engineers can develop solutions to minimize them.

The combination of customized array design, high channel counts and various optimized algorithms guarantee the best possible results for acoustic imaging in wind tunnels. Our advanced system is engineered to deliver the highest precision, ensuring accurate and detailed acoustic imaging in real time. Since time is a crucial factor in wind tunnel testing, we guarantee the fastest possible data transmission and processing.