When sound is annoying, its name is noise. When noise is the problem for any reason like high and dangerous levels for the human ear, malfunction of and failures in machines, lacking acoustic comfort or sound quality, … we measure, visualize and localize the sources and finally analyze them.

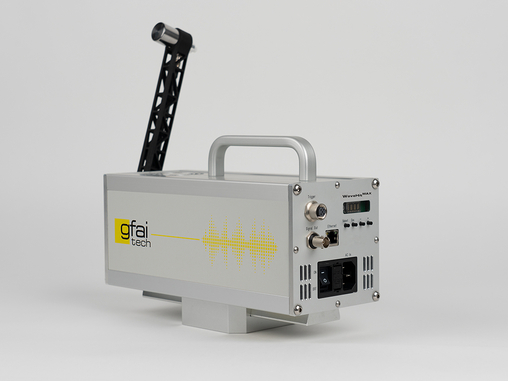

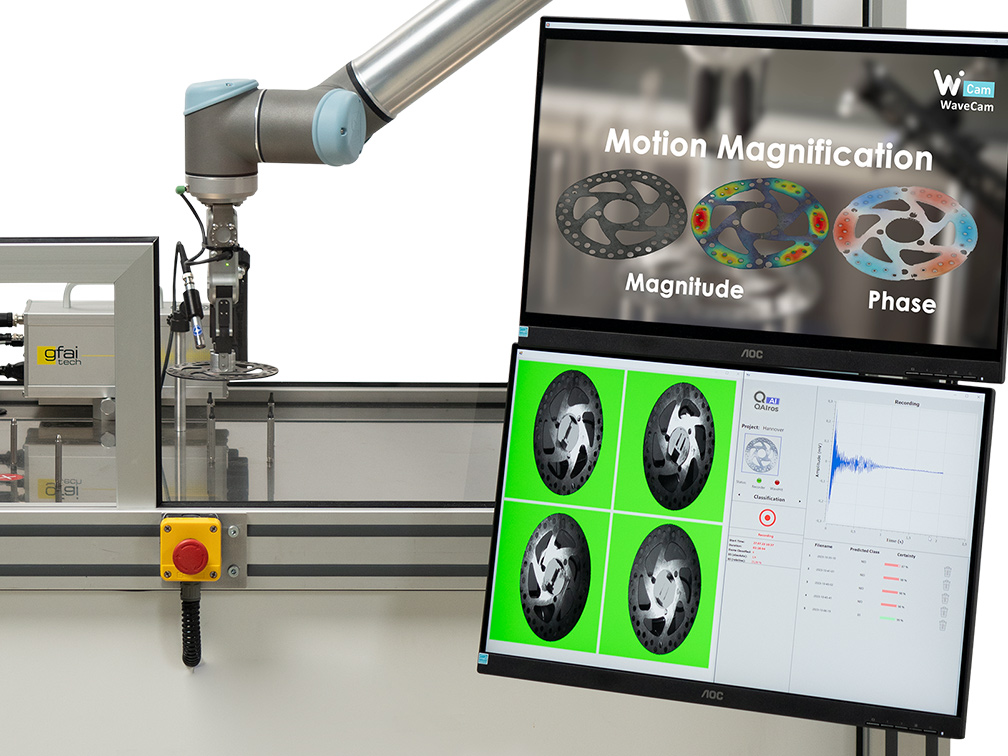

Our algorithmic tools are three localization techniques: beamforming, intensity and holography. The Acoustic Camera applies all three techniques in conjuction with different microphone arrays.

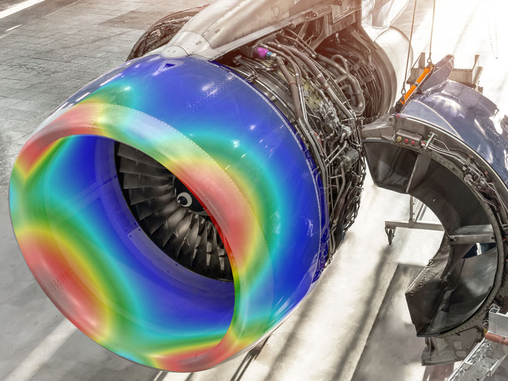

The measurement results show the main and secondary sound sources in acoustic maps as well as the related frequency range. This useful data is provided as photo, video, or 3D model with a spectral-colors overlay.

Remember when you analyse and reduce noise, the first step is to localize it.

Use the best tool, use the Acoustic Camera.