A new perspective on the invisible

In industries such as manufacturing, energy, or pharmaceuticals, every detail can make the difference between efficiency and downtime. Vibrations that are invisible to the naked eye may hold critical clues to operational irregularities. But conventional measurement systems often provide only partial insights – especially when applied to complex systems.

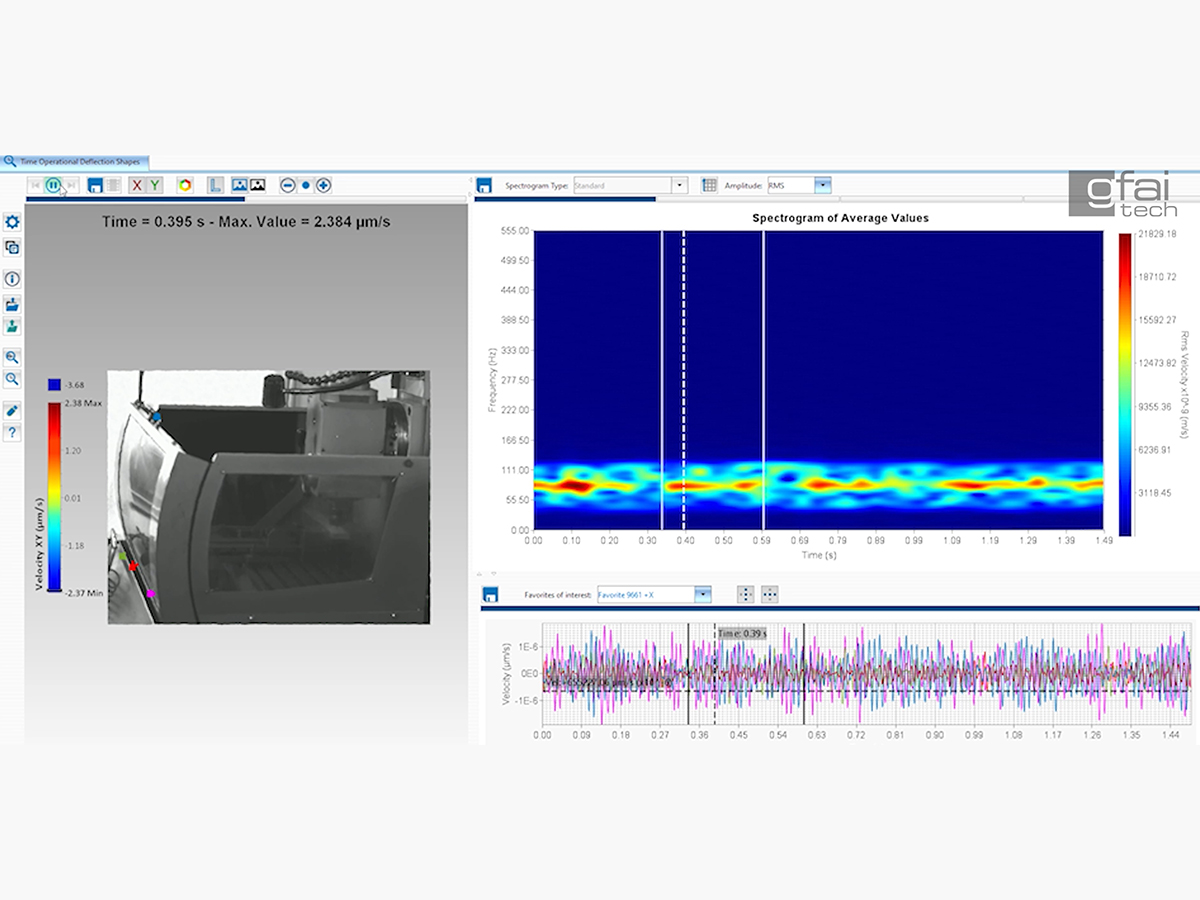

This new video-based technology replaces point-by-point data with full-field visualization. Videos – recorded with standard or high-speed cameras – are processed by dedicated software. Every pixel becomes a virtual measurement point, whose movement over time is calculated and visualized. This allows engineers to detect even the tiniest vibrations in the micrometer range – with a resolution of up to 1/10,000.

From guesswork to data-driven diagnostics

"What you can see, you can understand," says Philip Höhna, Managing Director of gfai tech GmbH. "With WaveCam, our customers can instantly pinpoint where a problem originates – instead of measuring for hours, interpreting results, and hoping for the best." Whether used on steel frames, wind turbines or rotating components, the software enables intuitive fault detection and reliable documentation – even for cross-functional teams.

Just three components: camera, laptop, software

The benefits are clear: no sensor wiring, no special calibration, no physical contact. All you need is a camera, a laptop, and the software – a setup that works both in the lab and directly on site. For lower frequencies, smartphone video recordings are sufficient; for higher-frequency vibration analysis, high-speed cameras can be used.

The technology unfolds its full potential in condition monitoring, fault diagnostics, and prototype testing – fast, cost-effective, and highly visual.

Applications that deliver real-world value

- Vehicle design: analyzing deformation in doors or tires at high speeds

- Industrial machinery: identifying resonances in rotating parts

- Construction & infrastructure: assessing bridges, facades, or concrete structures

- Simulation & prototyping: validating FEM models through real-world vibration patterns

Find out how vibration analysis with WaveCam works in practice!

Our experts will show you live which cameras are suitable, exactly how the technology works and what results you can expect.

Take part in the free live webinar

"WaveCam: Transforming video into vibration insights".

Date: September 3, 2025

Time: 10:00 AM & 6:00 PM (UTC+2)

Location: Online (English language)

Please registerhere: