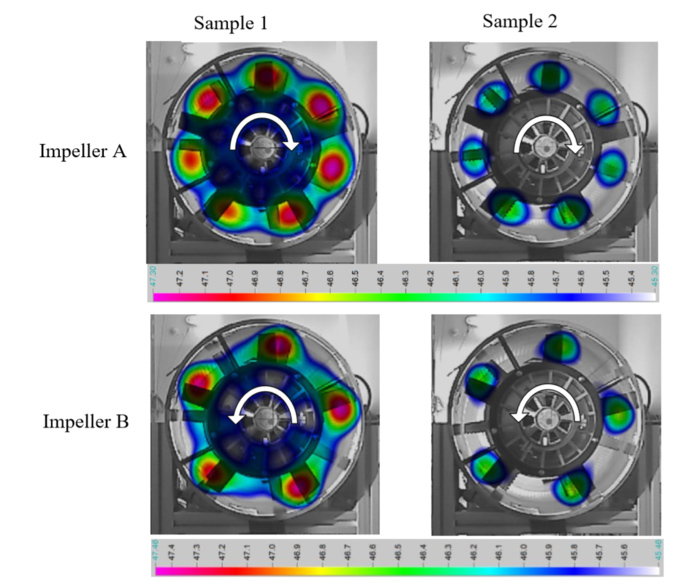

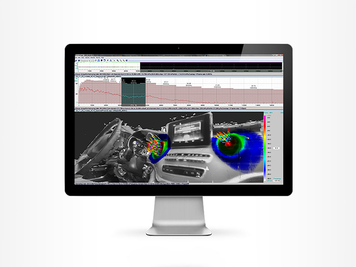

In fan blade design, a main goal is to minimize the noise emissions made by the fan. Thus, different design modifications need to be examined regarding their noise emissions. The Acoustic Camera is a helpful tool in this task. "Investigations on noise sources on a contra-rotating axial fan with different modifications" , a paper published by R. Krause, C. Friebe, M. Kerscher and C. Puhle at fan2018, shows how the Acoustic Camera was applied to examine design modifications of axial fans.

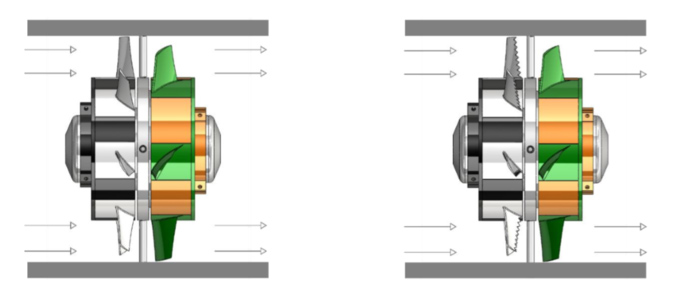

Axial fans are the most common type of fans and are used in many fields including wind tunnels and cooling towers. They work by the continuous rotation of an axial impeller. Similar to aircraft propellers, the gas flows in an axial direction, parallel to the shaft about which the blades rotate. Due to this working principle, swirls occur at the trailing edge of the blades. These swirls may have unfavourable influence on subsequent devices, e.g. higher pressure drop or lower heat transfer coefficient. Thus, they are unwanted and should be minimized.

Design parameters for fan blades include power, flow rate, pressure rise and efficiency. Static pressure rise is one evaluation criterion for the fan efficiency. To rise the efficiency, the dynamic pressure of the swirls should be converted into a static pressure rise. One common way to increase the efficiency is to install contra-rotating fans (CRF), because they provide high power density and high efficiency. Nevertheless, this type is also known for problematic noise behaviour because of the interaction of both wheels with different directions of rotation. This problematic noise behavior makes a CRF the perfect testing object for sound analyses of fans using the Acoustic Camera.