Whether washing machines, coffee machines or turbo trainers: household appliances and consumer products should should aim to be exceptionally quiet while delivering high-quality sound.

Acoustic measurement methods are therefore used both in the development phase and in the maintenance and servicing of devices and equipment, and vibration analyses are carried out to localize noises and optimize products.

Our various Acoustic Cameras, whether AC Pro systems or all-in-one sound cameras, are used in the identification and analysis of noise sources, troubleshooting, and sound design optimization. By quickly identifying these noise sources and providing solutions, manufacturers and developers can save time, adapt their products more quickly to customer requirements, and effectively eliminate potential defects.

In product development, the Acoustic Camera also helps to ensure that the next generation of household and leisure appliances has a first-class sound design. This improves the customer experience and increases the appeal of the products. Acoustic maps help identify where manufacturers need to target to reduce sound emissions from appliances, machinery and equipment and comply with regulatory limits. The areas of application are as diverse as the products themselves: Mobile or stationary, small or large - sound measurements can be carried out on a wide variety of equipment.

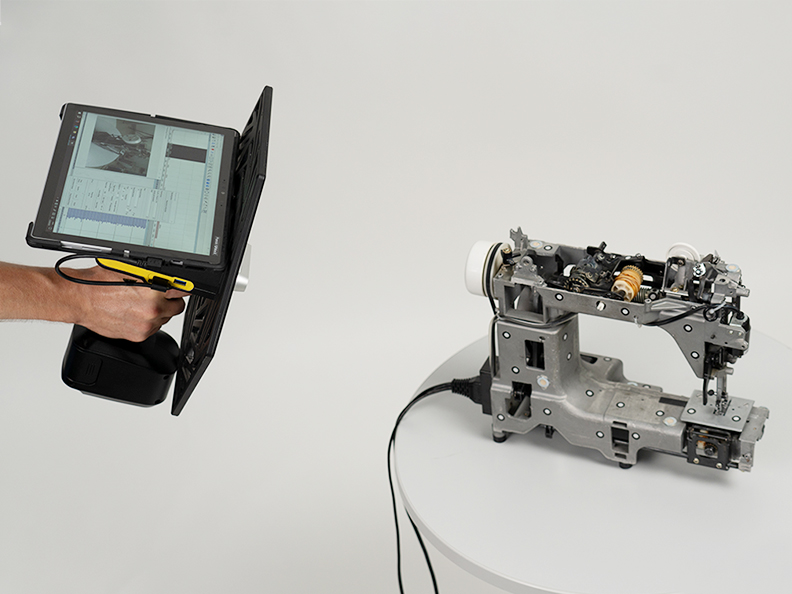

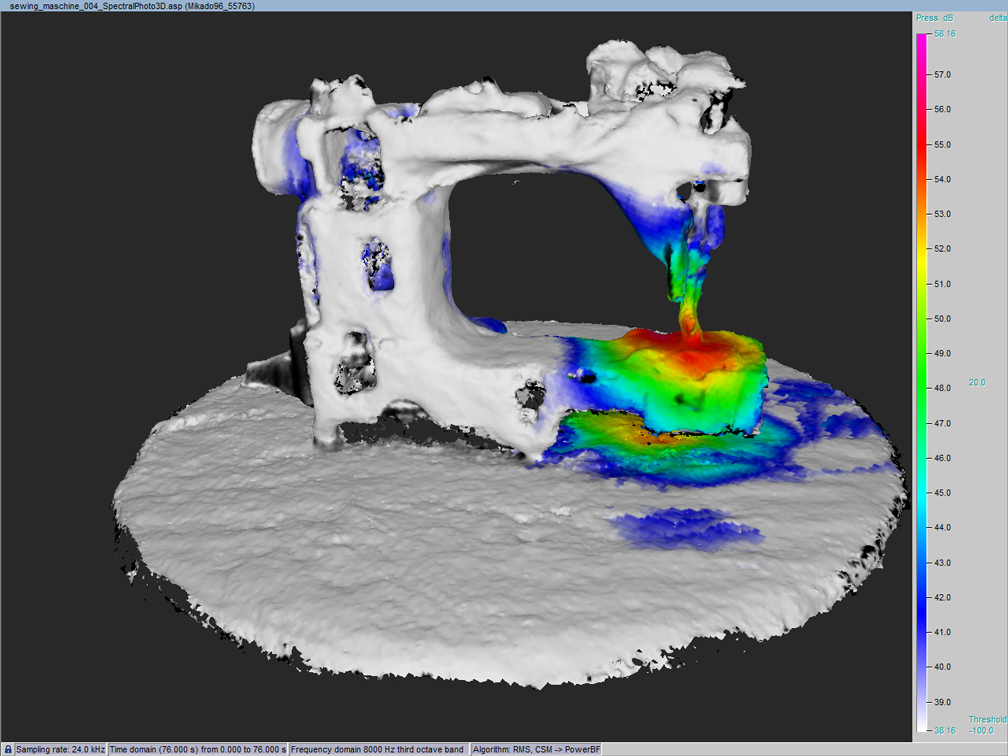

Acoustic measurements with the soundcam Mikado

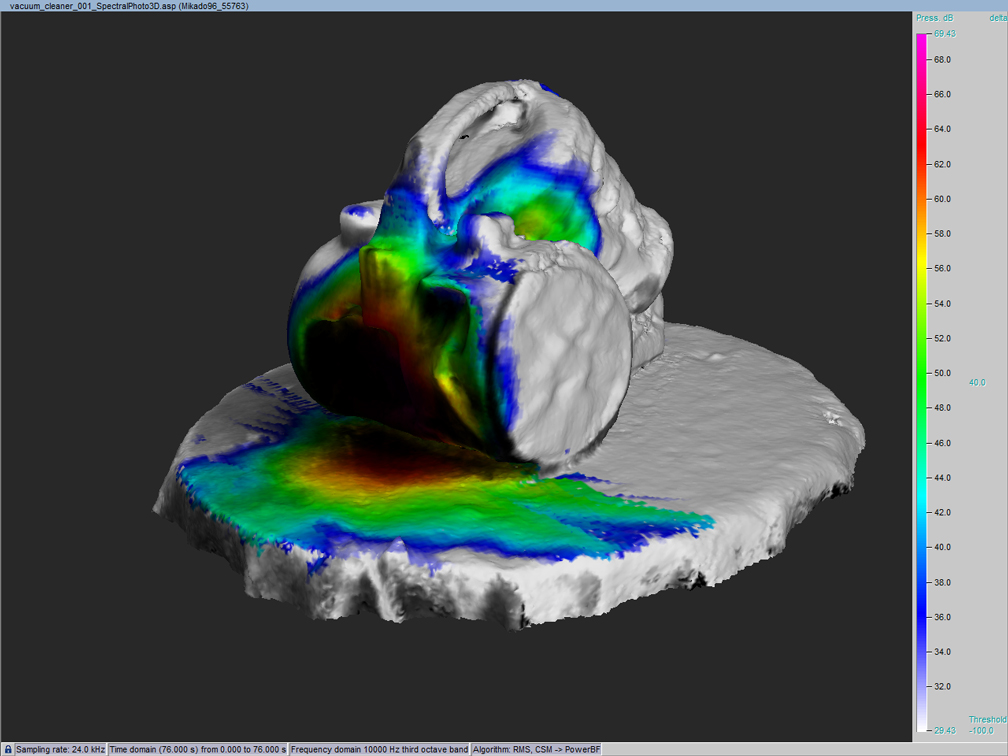

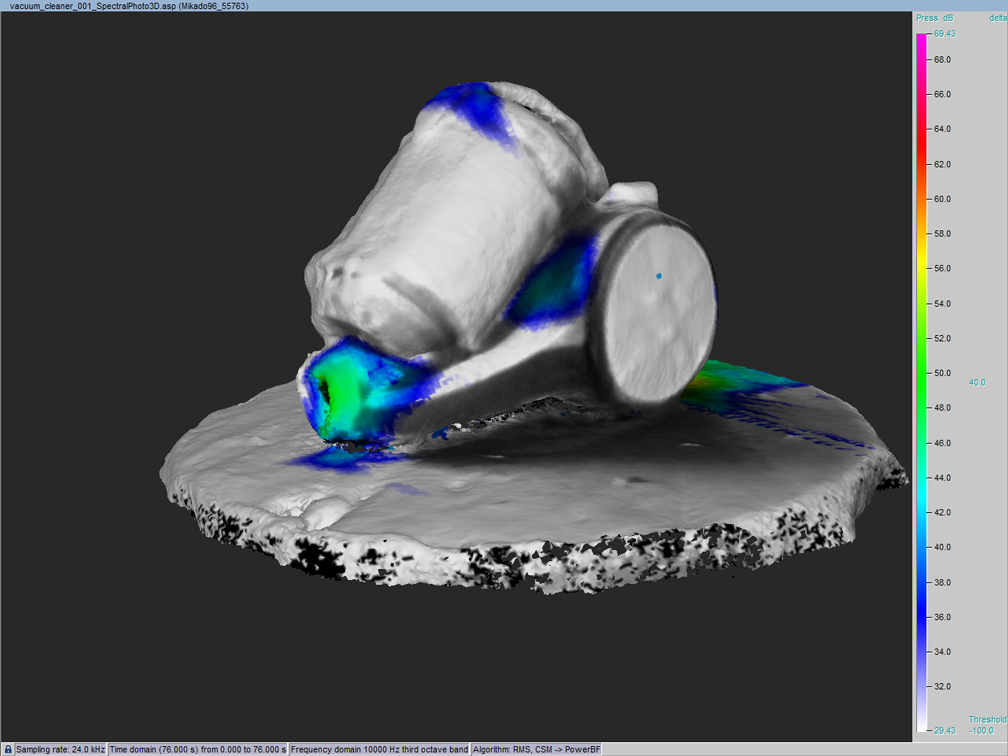

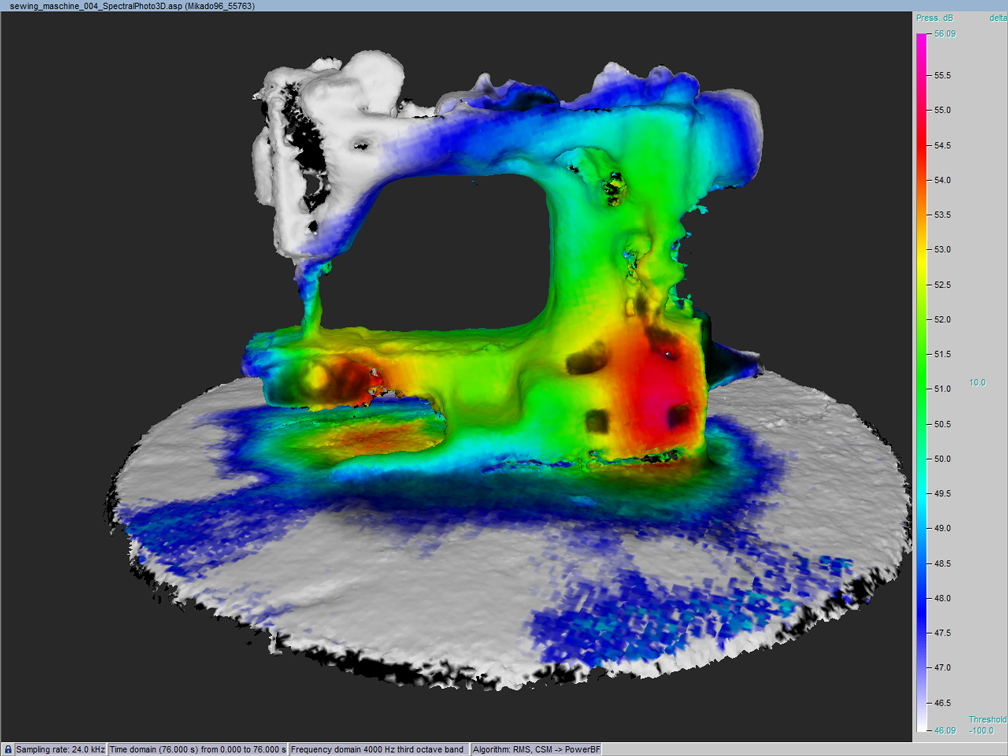

The following examples show acoustic measurements on a vacuum cleaner and a sewing machine. They were performed with the all-in-one sound camera Mikado. During the measurement, a 3D object was simultaneously scanned in real time, and calculations were made using gfai tech's advanced power beamforming algorithm. This enabled the acquisition of a detailed "acoustic fingerprint" of the measured object with only one measurement.

The high quality of the acoustic maps is due to both the DynaBeam method and the power beamforming algorithm, which were used in conjunction with the array's high microphone density. The resulting images are an impressive example of state-of-the-art acoustic measurement technology and its application in industry.